Alginate (401) is cold soluble hydrocolloid extracted from brown seaweed. Alginate is used for heat stable gels, thickening, stabilising and film forming. The key to selecting the right alginate is managing the ionic content of the food.

Application

| Application | Function |

|---|---|

| Ice Cream & Sorbet | Controls ice crystallisation without serum separation. Improves texture and whipping. |

| Meat injection | Improves succulence and yield. Prevents shrinkage upon cooking. |

| Ground Meat emulsions | Improves succulence and yield. Prevents shrinkage upon cooking. |

| Artificial Cherries | Provides gel structure and heat stability. |

| Reformed Onion rings | Provides gel network and heat stability. |

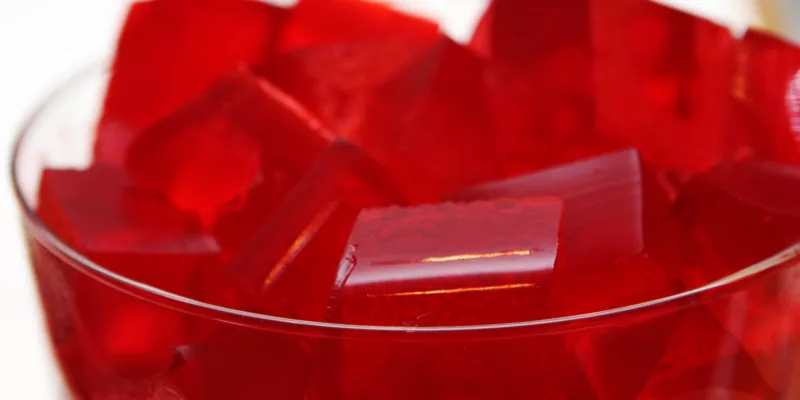

| Cold water set jellies | Produces a firm gel network within 1 hour using cold water. |

| Bakery Creams | Instant gelation and thickening. Creams made with alginate are also heat stable. |

| Fruit fillings | Imparts bake stability. Improves flavour release when used with starch. |

| Salad Dressings | Assists in emulsification, thickening and stabilisation. |

Chemistry

Alginate (E400-E404) is produced by brown seaweeds (Phaeophyceae, mainly Laminaria).

Alginate is made up of long chains of two monomers — guluronic acid and mannuronic acid. The chains can be made of all one monomer, or mixtures of each. The stems of kelp are made of chains with more guluronic acid, and the leaves (fronds) have more mannuronic acid. Guluronic chains bind tightly to calcium; in mannuronic chains the calcium is more easily replaced by sodium, allowing the fibres to swell easily.

Alginate is the collective name used for the salts and organic derivative of Alginic Acid. Alginic acid is insoluble; therefore the food industry generally uses the soluble sodium salt of propylene glycol alginate.

The most widely known use of sodium alginate is in the production of calcium alginate gels. Calcium alginate is insoluble and in calcium ions are released slowly into a solution of sodium alginate a smooth homogeneous gel is formed. Gels can be formed at 0.5% w/w alginate and are thermally irreversible. They are generally clear and vary in texture, from brittle to elastic depending on the calcium: sodium ratio, the pH and source of alginate. Gel strength can similarly be altered from a weak pumpable gel to a rigid sliceable gel by the careful balancing of calcium ions, sequestrant, and calcium releasing agents.

Properties

Alginate is cold water-soluble. A hydration time of 5 – 30 minutes is normal but this is dependent upon particle size. The solutions vary in viscosity and appearance depending on the grade. The addition of calcium ions increases the viscosity considerably. In most cases sugar and salt make little difference to the solution, except by increasing the effective alginate concentration and inhibiting hydration.

The texture of alginate gels can be altered from elastic to brittle, weak to strong by altering the ration of the ingredients. Gels are thermally irreversible.